Below is the rolling news feed from Zimmer and Peacock. Our news feed represents that Zimmer and Peacock is a fast moving active company with lots of well-directed activity.

Serial number SIA FoodSense

You can find your Serial Number under the device.

One hour consulting with ZP

One hour consulting - specific to client

Going through records for client

240,00 €

Final price

Free shipping to the following countries: Afghanistan, Albania, Andorra, Angola, Anguilla, Antarctica, Antigua and Barbuda, Armenia, Netherlands Antilles, United Arab Emirates , Algeria, American Samoa, Argentina, Aruba, Australia, Austria, Azerbaijan, Bahamas, Bahrain, Bangladesh, Barbados, Belarus, Belgium, Belize, Benin, Bermuda, Bhutan, Bolivia, Bosnia and Herzegovina, Botswana, Bouvet Island, Brazil, British Indian Ocean Territory, British Virgin Islands, Brunei, Bulgaria, Burkina Faso, Burundi, Cambodia, Cameroon, Canada, Cape Verde, Cayman Islands, Central African Republic, Chad, Chile, China, Christmas Island, Cocos [Keeling] Islands, Colombia, Comoros, Congo - Brazzaville, Congo - Kinshasa, Cook Islands, Costa Rica, Côte d’Ivoire, Croatia, Cuba, Cyprus, Czech Republic, Denmark, Djibouti, Dominica, Dominican Republic, Ecuador, Egypt, El Salvador, Equatorial Guinea, Eritrea, Estonia, Ethiopia, Falkland Islands, Faroe Islands, Fiji, Finland, France, French Guiana, French Polynesia, French Southern Territories, Gabon, Gambia, Georgia, Germany, Ghana, Gibraltar, Greece, Greenland, Grenada, Guadeloupe, Guam, Guatemala, Guinea, Guinea-Bissau, Guyana, Haiti, Heard Island and McDonald Islands, Honduras, Hong Kong SAR China, Hungary, Iceland, India, Indonesia, Iran, Iraq, Ireland, Israel, Italy, Jamaica, Japan, Jordan, Kazakhstan, Kenya, Kiribati, Kuwait, Kyrgyzstan, Laos, Latvia, Lebanon, Lesotho, Liberia, Libya, Liechtenstein, Lithuania, Luxembourg, Macau SAR China, Macedonia, Madagascar, Malawi, Malaysia, Maldives, Mali, Malta, Marshall Islands, Martinique, Mauritania, Mauritius, Mayotte, Mexico, Micronesia, Moldova, Monaco, Mongolia, Montenegro, Montserrat, Morocco, Mozambique, Myanmar [Burma], Namibia, Nauru, Nepal, Netherlands, New Caledonia, New Zealand, Nicaragua, Niger, Nigeria, Niue, Norfolk Island, Northern Mariana Islands, North Korea, Norway, Oman, Pakistan, Palau, Palestinian Territories, Panama, Papua New Guinea, Paraguay, Peru, Philippines, Pitcairn Islands, Poland, Portugal, Puerto Rico, Qatar, Réunion, Romania, Russia, Rwanda, Saint Barthélemy, Saint Helena, Saint Kitts and Nevis, Saint Lucia, Saint Martin, Saint Pierre and Miquelon, Saint Vincent and the Grenadines, Samoa, San Marino, São Tomé and Príncipe, Saudi Arabia, Senegal, Serbia and Montenegro, Seychelles, Sierra Leone, Singapore, Slovakia, Slovenia, Solomon Islands, Somalia, South Africa, South Georgia and the South Sandwich Islands, South Korea, Spain, Sri Lanka, Sudan, Suriname, Svalbard and Jan Mayen, Swaziland, Sweden, Switzerland, Syria, Taiwan, Tajikistan, Tanzania, Thailand, Timor-Leste, Togo, Tokelau, Tonga, Trinidad and Tobago, Tunisia, Turkey, Turkmenistan, Turks and Caicos Islands, Tuvalu, Uganda, Ukraine, United Kingdom, United States, Uruguay, U.S. Minor Outlying Islands, U.S. Virgin Islands, Uzbekistan, Vanuatu, Vatican City, Venezuela, Vietnam, Wallis and Futuna, Western Sahara, Yemen, Zambia, Zimbabwe Show more Show less

- Available

ZP SPE market opportunity

The global market for quality screen-printed electrodes (SPEs), integral to electrochemical research and development, is experiencing significant growth. In 2023, the market was valued at approximately $581.78 million and is projected to reach $1.49 billion by 2034, reflecting a compound annual growth rate (CAGR) of 8.9%

Please join ZP in our live webinar where we discuss distribution opportunities for our World Class Screen Printed Electrodes, and demonstrate our unique quality and super competitive pricing.

ZP School Videos

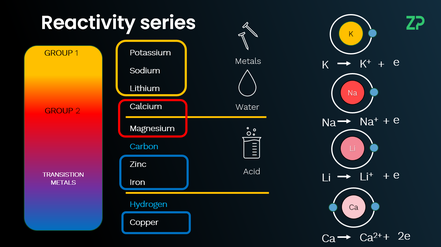

Reactivity Series

In this video we explore the reactivity series of metals, ranking them based on their reactions with water and acids. We'll break down how metals lose electrons to form positive ions and explain key displacement reactions and use the series to predict metal reactivity. From explosive potassium reactions to inert copper, this lesson makes chemistry clear and practical. Watch to deepen your understanding of metal reactivity.

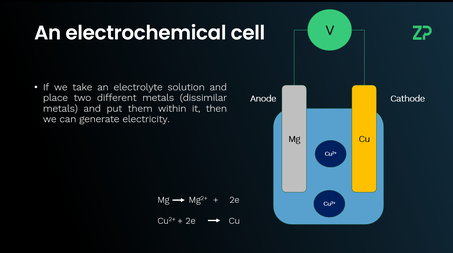

Cells and batteries

This video explains the difference between cells and batteries, electrochemical cells, and voltage potential. A cell consists of two different metals in an electrolyte, generating voltage. Connecting multiple cells in series creates a battery. The reactivity series helps predict voltages from metals positions in the series - farther apart, like magnesium and copper, produce higher voltage than closer ones, like magnesium and zinc. It also covers rechargeable (e.g., lead acid, lithium-ion) and non-rechargeable batteries (e.g., AA, AAA). Lead acid batteries start gasoline cars, while lithium-ion batteries power phones and electric vehicles. Batteries are essential in daily life, from household devices to transportation.

ZP Education Kit - Educate and Inspire

The ZP Education Kit is part of ZP's STEM Mission to Educate and Inspire all generations of scientists.

Experiment One - ZP Education Kit

This experiment uses cyclic voltammetry to study the redox reactions of potassium ferrocyanide. The SenseIt All app is configured in voltammetry mode, with settings: -200 mV to +600 mV, 100 mV/s scan rate, 100 µA current limit, one cycle, lasting 19 seconds. A 50 µL solution of 5 mM ferrocyanide is applied to screen-printed electrodes. The app records time versus current for the oxidation of ferrocyanide to ferricyanide and reduction of ferricyanide to ferrocyanide. Results are uploaded to the cloud (Julie), accessible via the app for data analysis. This process enables visualization of oxidation and reduction waves for detailed examination.

-

Set Up the Equipment and App:

- Ensure you have the SenseIt All app set to cyclic voltammetry mode.

- Name the experiment within the app for easy retrieval later.

- Confirm that the data will be saved in the cloud (e.g., in "Djuli").

-

Prepare the Solution and Electrode:

- Use 50 µL of 5 mM potassium ferrocyanide solution.

- Apply the solution onto the screen-printed electrodes.

-

Configure the Settings:

- Duration: 19 seconds.

- Initial Voltage: -200 mV.

- Final Voltage: +600 mV.

- Scan Rate: 100 mV/s.

- Cycles: 1.

- Current Limit: 100 µA.

-

Start the Experiment:

- Begin the cyclic voltammetry measurement via the app.

- The experiment will record time versus current during:

- Oxidation of ferrocyanide to ferricyanide.

- Reduction of ferricyanide to ferrocyanide.

-

Save and View Results:

- Confirm that the data has been uploaded to the cloud.

- Refresh the data view in the app to locate and access the saved results.

- Review the oxidation and reduction waves for ferrocyanide/ferricyanide.

-

Analyze Data:

- Use the app to display and interpret the collected data for oxidation and reduction.

With these steps, anyone familiar with the equipment and app should be able to replicate the experiment successfully. Let me know if you need clarification or additional details!

Experiment Two - ZP Education Kit

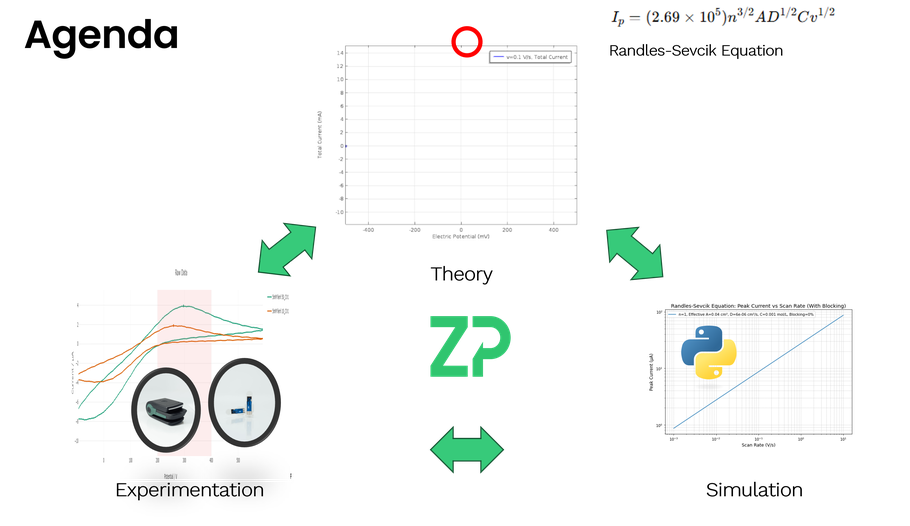

These experiments demonstrate the relationship between cyclic voltammetry peak height and the square root of the scan rate, as described by the Randles-Sevcik equation. A HyperValue carbon electrode and 50 µL of 5 mM potassium ferrocyanide were used. The SenseIt All app, paired via Bluetooth with the potentiostat, conducted scans at 50, 100, 200, and 300 mV/s. Data was uploaded to the cloud for visualization and analysis. The results confirmed that peak height is proportional to the square root of the scan rate under diffusion control, emphasizing the importance of fast assays in practical applications, such as healthcare diagnostics.

-

Set Up the Equipment and App:

- Ensure you have the SenseIt All app connected to the potentiostat via Bluetooth.

- Scan the QR code to change the app mode for conducting multiple experiments in sequence.

- Name the experiment (e.g., “Test 8”) and save it within a cluster (e.g., “Demo”) for easy data retrieval later.

-

Prepare the Solution and Electrode:

- Use a HyperValue carbon electrode.

- Apply 50 µL of 5 mM potassium ferrocyanide solution to the electrode.

-

Experiment Settings:

- Configure the app to run four experiments in sequence with scan rates of:

- 50 mV/s (slowest scan).

- 100 mV/s.

- 200 mV/s.

- 300 mV/s (fastest scan).

- Configure the app to run four experiments in sequence with scan rates of:

-

Start the Experiments:

- Press “Start” in the app to initiate the first scan at 50 mV/s.

- Subsequent scans will automatically follow at the specified rates (100, 200, and 300 mV/s).

-

Data Upload and Analysis:

- Once the experiments are complete, confirm the data has been uploaded to the cloud.

- Access the cloud data via the app and locate your test (e.g., “Test 8”).

-

Visualize and Analyze Results:

- View cyclic voltammograms for each scan rate (50, 100, 200, and 300 mV/s).

- Edit the data presentation to enhance clarity or align with desired conventions.

- Observe the relationship between peak height and the square root of scan rate, as characterized by the Randles-Sevcik equation.

-

Teaching Insights:

- Reflect on the importance of fast assays in practical applications, emphasizing their relevance in real-world scenarios like healthcare.

This sequence should enable others to repeat the experiment while understanding its teaching objectives. Let me know if you'd like further elaboration!

Experiment Three - ZP Education Kit

Experiment Three in the ZP educational kit showcases the real-world application of voltammetry by analyzing caffeine content in Red Bull. A sample is prepared by mixing 100 µL of Red Bull with 100 µL of ZP caffeine buffer. Using the SenseIt All app in “Caffeine Beverage Mode,” a 50 µL aliquot is placed on the sensor, and the assay is initiated. Real-time signals display interference peaks and the caffeine peak. Results are uploaded to the cloud for data analysis. The caffeine concentration is calculated and verified against the label (e.g., 0.328 mg/g vs. 0.3 mg/g), demonstrating voltammetry’s practical utility.

Here’s a step-by-step guide for repeating Experiment Three from the ZP educational kit:

-

Objective: Understand that voltammetry can be applied in real-world assays, such as analyzing caffeine in Red Bull.

-

Prepare the Sample:

- Measure 100 µL of Red Bull.

- Measure 100 µL of ZP’s caffeine buffer (refer to the specific product details).

- Combine the two solutions in a small vial.

-

Set Up the Equipment:

- Use the SenseIt All app on your phone.

- Switch from “Cyclic Voltammetry Mode” to “Caffeine Beverage Mode” by scanning the appropriate QR code.

- Name the experiment (e.g., “Red Bull”) for data organization in the Julie Cloud.

-

Run the Assay:

- Pipette 50 µL of the prepared sample onto the sensor.

- Initiate the assay by pressing “Start” in the app.

- Monitor the process in real-time as signals are recorded.

-

Data Analysis:

- Observe the real-time signal, noting interference peaks (e.g., theobromine) and the caffeine peak.

- Confirm data upload completion to the cloud.

-

Verify Results:

- Check the caffeine concentration on the Red Bull can (typically 0.3 mg/g).

- Compare with the experimental result (e.g., 0.328 mg/g).

-

Access Data:

- Refresh the Julie Cloud interface to locate the experiment file (e.g., “Red Bull”).

- Review the raw signal, peak identification, and how peak height correlates to caffeine concentration.

This experiment emphasizes the practical applications of voltammetry beyond the lab, particularly for real-world scenarios. Let me know if you need further clarification!

Experiment Four - ZP Education Kit

Experiment Four in the ZP educational kit showcases copper electroplating.

Electroplating is a fascinating process that allows metals to be deposited onto surfaces using electrical currents. In this experiment, copper is plated onto a working electrode in real time using a small-scale setup.

The demonstration begins with setting up a potentiostat (a controlled power supply) and preparing a copper sulfate solution. A precise 50-microliter drop is applied to the electrode, and a voltage of -700 millivolts is set for 240 seconds. As the experiment progresses, copper ions in the solution move toward the cathode, where they gain electrons and form a thin layer of copper metal. Under a microscope, the process is visible — the initial black electrode slowly turns orange as the copper deposits.

This setup is ideal for educational purposes, offering an accessible and intrinsically safe way to explore electroplating. The small-scale approach minimizes risks while allowing for real-time observation of the metal deposition process. The ability to visually track the experiment offers deeper insights into the mechanics of copper electroplating.

Absolutely! Here’s a step-by-step experimental protocol for electroplating copper, designed for clarity and ease of execution:

Electroplating Copper: Experimental Protocol

Materials Required:

- Potentiostat (or power supply) to control voltage

- Screen-printed electrode as the working electrode (cathode)

- Copper sulfate solution (50 mg/mL or 50,000 ppm) as the electrolyte

- Microscope for real-time observation

- Pipette for precise solution application

- Smartdevice to control the experiment

Procedure:

-

Prepare the Experimental Setup:

- Place the screen-printed electrode securely on the workstation.

- Position the microscope to visualize the electrode surface.

- Connect the potentiostat to the electrode, ensuring proper configuration.

-

Apply the Electrolyte Solution:

- Using a pipette, carefully deposit 50 microliters of copper sulfate solution onto the electrode.

- Ensure an even spread over the surface for uniform deposition.

-

Set Electroplating Parameters:

- Configure the potentiostat:

- Voltage: -700 millivolts

- Duration: 240 seconds (4 minutes)

- Start the measurement via the control interface (smartphone/computer).

- Configure the potentiostat:

-

Observe the Electroplating Process:

- Monitor changes in the electrode using the microscope.

- As copper ions gain electrons, copper metal deposits onto the cathode.

- Note the color change from black to orange as copper forms.

-

Completion and Analysis:

- Once the 4-minute deposition is complete, stop the process.

- Carefully remove excess solution to examine the plated copper.

Conclusion:

This experiment is an excellent educational demonstration of electroplating at a small scale. The ability to visualize deposition in real time provides deeper insight into the process, making it ideal for learning environments.

Would you like any additional details or modifications?

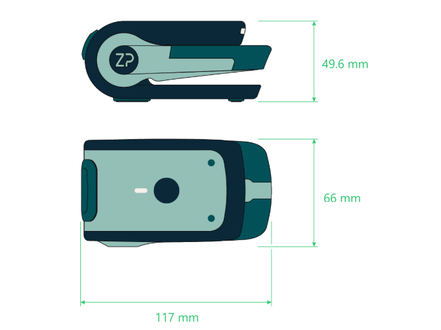

FoodSense Generation Four Shipping Detals

HS Code - 9031.80

Weight of package - 1.8 kg

Dimensions - 34 x 18 x 8 cm

ZP Webinar for Distributors and Resellers

ZP is holding a webinar specifically for current and potential distributors and resellers of ZP's technologies, from:

- Chilli Testing

- Ginger Testing

- Caffeine Testing

- Heavy Metal Testing

- Electrochemistry Technologies

- Screen Printed Electrodes

We are holding two sessions the morning session will work for Asia whilst the afternoon will work well for the Americas.

Potential Distributor/Reseller Form

You have been directed to this form as a potential distributor/reseller of ZP technology.

Please complete the form in the button.

CGM Technology and meeting

Thank you for your enquiry regarding CGM technology and/or a meeting.

Science/Engineering/Consultative/Administrative/Contractual Services from ZP

ZP offers engineering services around our core competencies of electrochemical sensors and biosensors. Other services that can also be purchased using this store item includes, administrative services and legal support, including contracts and NDAs.

Engineering services from ZP

Engineering services from Zimmer and Peacock

810,00 €

Final price

Free shipping to the following countries: Afghanistan, Albania, Andorra, Angola, Anguilla, Antarctica, Antigua and Barbuda, Armenia, Netherlands Antilles, United Arab Emirates , Algeria, American Samoa, Argentina, Aruba, Australia, Austria, Azerbaijan, Bahamas, Bahrain, Bangladesh, Barbados, Belarus, Belgium, Belize, Benin, Bermuda, Bhutan, Bolivia, Bosnia and Herzegovina, Botswana, Bouvet Island, Brazil, British Indian Ocean Territory, British Virgin Islands, Brunei, Bulgaria, Burkina Faso, Burundi, Cambodia, Cameroon, Canada, Cape Verde, Cayman Islands, Central African Republic, Chad, Chile, China, Christmas Island, Cocos [Keeling] Islands, Colombia, Comoros, Congo - Brazzaville, Congo - Kinshasa, Cook Islands, Costa Rica, Côte d’Ivoire, Croatia, Cuba, Cyprus, Czech Republic, Denmark, Djibouti, Dominica, Dominican Republic, Ecuador, Egypt, El Salvador, Equatorial Guinea, Eritrea, Estonia, Ethiopia, Falkland Islands, Faroe Islands, Fiji, Finland, France, French Guiana, French Polynesia, French Southern Territories, Gabon, Gambia, Georgia, Germany, Ghana, Gibraltar, Greece, Greenland, Grenada, Guadeloupe, Guam, Guatemala, Guinea, Guinea-Bissau, Guyana, Haiti, Heard Island and McDonald Islands, Honduras, Hong Kong SAR China, Hungary, Iceland, India, Indonesia, Iran, Iraq, Ireland, Israel, Italy, Jamaica, Japan, Jordan, Kazakhstan, Kenya, Kiribati, Kuwait, Kyrgyzstan, Laos, Latvia, Lebanon, Lesotho, Liberia, Libya, Liechtenstein, Lithuania, Luxembourg, Macau SAR China, Macedonia, Madagascar, Malawi, Malaysia, Maldives, Mali, Malta, Marshall Islands, Martinique, Mauritania, Mauritius, Mayotte, Mexico, Micronesia, Moldova, Monaco, Mongolia, Montenegro, Montserrat, Morocco, Mozambique, Myanmar [Burma], Namibia, Nauru, Nepal, Netherlands, New Caledonia, New Zealand, Nicaragua, Niger, Nigeria, Niue, Norfolk Island, Northern Mariana Islands, North Korea, Norway, Oman, Pakistan, Palau, Palestinian Territories, Panama, Papua New Guinea, Paraguay, Peru, Philippines, Pitcairn Islands, Poland, Portugal, Puerto Rico, Qatar, Réunion, Romania, Russia, Rwanda, Saint Barthélemy, Saint Helena, Saint Kitts and Nevis, Saint Lucia, Saint Martin, Saint Pierre and Miquelon, Saint Vincent and the Grenadines, Samoa, San Marino, São Tomé and Príncipe, Saudi Arabia, Senegal, Serbia and Montenegro, Seychelles, Sierra Leone, Singapore, Slovakia, Slovenia, Solomon Islands, Somalia, South Africa, South Georgia and the South Sandwich Islands, South Korea, Spain, Sri Lanka, Sudan, Suriname, Svalbard and Jan Mayen, Swaziland, Sweden, Switzerland, Syria, Taiwan, Tajikistan, Tanzania, Thailand, Timor-Leste, Togo, Tokelau, Tonga, Trinidad and Tobago, Tunisia, Turkey, Turkmenistan, Turks and Caicos Islands, Tuvalu, Uganda, Ukraine, United Kingdom, United States, Uruguay, U.S. Minor Outlying Islands, U.S. Virgin Islands, Uzbekistan, Vanuatu, Vatican City, Venezuela, Vietnam, Wallis and Futuna, Western Sahara, Yemen, Zambia, Zimbabwe Show more Show less

- Available

Potentiostat, carbon electrode, meldola blue electrode

Thank you for your enquiry regarding potentiostats, carbon screen printed electrode and Meldola blue screen printed electrodes.

Science/Engineering/Consultative/Administrative/Contractual Services from ZP

ZP offers engineering services around our core competencies of electrochemical sensors and biosensors. Other services that can also be purchased using this store item includes, administrative services and legal support, including contracts and NDAs.

Engineering services from ZP

Engineering services from Zimmer and Peacock

810,00 €

Final price

Free shipping to the following countries: Afghanistan, Albania, Andorra, Angola, Anguilla, Antarctica, Antigua and Barbuda, Armenia, Netherlands Antilles, United Arab Emirates , Algeria, American Samoa, Argentina, Aruba, Australia, Austria, Azerbaijan, Bahamas, Bahrain, Bangladesh, Barbados, Belarus, Belgium, Belize, Benin, Bermuda, Bhutan, Bolivia, Bosnia and Herzegovina, Botswana, Bouvet Island, Brazil, British Indian Ocean Territory, British Virgin Islands, Brunei, Bulgaria, Burkina Faso, Burundi, Cambodia, Cameroon, Canada, Cape Verde, Cayman Islands, Central African Republic, Chad, Chile, China, Christmas Island, Cocos [Keeling] Islands, Colombia, Comoros, Congo - Brazzaville, Congo - Kinshasa, Cook Islands, Costa Rica, Côte d’Ivoire, Croatia, Cuba, Cyprus, Czech Republic, Denmark, Djibouti, Dominica, Dominican Republic, Ecuador, Egypt, El Salvador, Equatorial Guinea, Eritrea, Estonia, Ethiopia, Falkland Islands, Faroe Islands, Fiji, Finland, France, French Guiana, French Polynesia, French Southern Territories, Gabon, Gambia, Georgia, Germany, Ghana, Gibraltar, Greece, Greenland, Grenada, Guadeloupe, Guam, Guatemala, Guinea, Guinea-Bissau, Guyana, Haiti, Heard Island and McDonald Islands, Honduras, Hong Kong SAR China, Hungary, Iceland, India, Indonesia, Iran, Iraq, Ireland, Israel, Italy, Jamaica, Japan, Jordan, Kazakhstan, Kenya, Kiribati, Kuwait, Kyrgyzstan, Laos, Latvia, Lebanon, Lesotho, Liberia, Libya, Liechtenstein, Lithuania, Luxembourg, Macau SAR China, Macedonia, Madagascar, Malawi, Malaysia, Maldives, Mali, Malta, Marshall Islands, Martinique, Mauritania, Mauritius, Mayotte, Mexico, Micronesia, Moldova, Monaco, Mongolia, Montenegro, Montserrat, Morocco, Mozambique, Myanmar [Burma], Namibia, Nauru, Nepal, Netherlands, New Caledonia, New Zealand, Nicaragua, Niger, Nigeria, Niue, Norfolk Island, Northern Mariana Islands, North Korea, Norway, Oman, Pakistan, Palau, Palestinian Territories, Panama, Papua New Guinea, Paraguay, Peru, Philippines, Pitcairn Islands, Poland, Portugal, Puerto Rico, Qatar, Réunion, Romania, Russia, Rwanda, Saint Barthélemy, Saint Helena, Saint Kitts and Nevis, Saint Lucia, Saint Martin, Saint Pierre and Miquelon, Saint Vincent and the Grenadines, Samoa, San Marino, São Tomé and Príncipe, Saudi Arabia, Senegal, Serbia and Montenegro, Seychelles, Sierra Leone, Singapore, Slovakia, Slovenia, Solomon Islands, Somalia, South Africa, South Georgia and the South Sandwich Islands, South Korea, Spain, Sri Lanka, Sudan, Suriname, Svalbard and Jan Mayen, Swaziland, Sweden, Switzerland, Syria, Taiwan, Tajikistan, Tanzania, Thailand, Timor-Leste, Togo, Tokelau, Tonga, Trinidad and Tobago, Tunisia, Turkey, Turkmenistan, Turks and Caicos Islands, Tuvalu, Uganda, Ukraine, United Kingdom, United States, Uruguay, U.S. Minor Outlying Islands, U.S. Virgin Islands, Uzbekistan, Vanuatu, Vatican City, Venezuela, Vietnam, Wallis and Futuna, Western Sahara, Yemen, Zambia, Zimbabwe Show more Show less

- Available

You can purchase packs of Meldola blue screen printed electrodes here.

You can find ZP's SIA potentiostat by clicking the button, this potentiostat has 0.4 nA resolution.

Microproject to support LMP91000

If you require technical support from ZP with regard to the LMP91000 please purchase a project below.

Micro Projects

A microproject from ZP is an effort of 16 hours of effort.

Any 3rd party costs will be charged at cost plus 15 %.

Micro Projects from ZP

16 hours of effort. All 3rd party costs will be charged in addition at cost plus 15 %

6.500,00 €

Final price

Free shipping to the following countries: Afghanistan, Albania, Andorra, Angola, Anguilla, Antarctica, Antigua and Barbuda, Armenia, Netherlands Antilles, United Arab Emirates , Algeria, American Samoa, Argentina, Aruba, Australia, Austria, Azerbaijan, Bahamas, Bahrain, Bangladesh, Barbados, Belarus, Belgium, Belize, Benin, Bermuda, Bhutan, Bolivia, Bosnia and Herzegovina, Botswana, Bouvet Island, Brazil, British Indian Ocean Territory, British Virgin Islands, Brunei, Bulgaria, Burkina Faso, Burundi, Cambodia, Cameroon, Canada, Cape Verde, Cayman Islands, Central African Republic, Chad, Chile, China, Christmas Island, Cocos [Keeling] Islands, Colombia, Comoros, Congo - Brazzaville, Congo - Kinshasa, Cook Islands, Costa Rica, Côte d’Ivoire, Croatia, Cuba, Cyprus, Czech Republic, Denmark, Djibouti, Dominica, Dominican Republic, Ecuador, Egypt, El Salvador, Equatorial Guinea, Eritrea, Estonia, Ethiopia, Falkland Islands, Faroe Islands, Fiji, Finland, France, French Guiana, French Polynesia, French Southern Territories, Gabon, Gambia, Georgia, Germany, Ghana, Gibraltar, Greece, Greenland, Grenada, Guadeloupe, Guam, Guatemala, Guinea, Guinea-Bissau, Guyana, Haiti, Heard Island and McDonald Islands, Honduras, Hong Kong SAR China, Hungary, Iceland, India, Indonesia, Iran, Iraq, Ireland, Israel, Italy, Jamaica, Japan, Jordan, Kazakhstan, Kenya, Kiribati, Kuwait, Kyrgyzstan, Laos, Latvia, Lebanon, Lesotho, Liberia, Libya, Liechtenstein, Lithuania, Luxembourg, Macau SAR China, Macedonia, Madagascar, Malawi, Malaysia, Maldives, Mali, Malta, Marshall Islands, Martinique, Mauritania, Mauritius, Mayotte, Mexico, Micronesia, Moldova, Monaco, Mongolia, Montenegro, Montserrat, Morocco, Mozambique, Myanmar [Burma], Namibia, Nauru, Nepal, Netherlands, New Caledonia, New Zealand, Nicaragua, Niger, Nigeria, Niue, Norfolk Island, Northern Mariana Islands, North Korea, Norway, Oman, Pakistan, Palau, Palestinian Territories, Panama, Papua New Guinea, Paraguay, Peru, Philippines, Pitcairn Islands, Poland, Portugal, Puerto Rico, Qatar, Réunion, Romania, Russia, Rwanda, Saint Barthélemy, Saint Helena, Saint Kitts and Nevis, Saint Lucia, Saint Martin, Saint Pierre and Miquelon, Saint Vincent and the Grenadines, Samoa, San Marino, São Tomé and Príncipe, Saudi Arabia, Senegal, Serbia and Montenegro, Seychelles, Sierra Leone, Singapore, Slovakia, Slovenia, Solomon Islands, Somalia, South Africa, South Georgia and the South Sandwich Islands, South Korea, Spain, Sri Lanka, Sudan, Suriname, Svalbard and Jan Mayen, Swaziland, Sweden, Switzerland, Syria, Taiwan, Tajikistan, Tanzania, Thailand, Timor-Leste, Togo, Tokelau, Tonga, Trinidad and Tobago, Tunisia, Turkey, Turkmenistan, Turks and Caicos Islands, Tuvalu, Uganda, Ukraine, United Kingdom, United States, Uruguay, U.S. Minor Outlying Islands, U.S. Virgin Islands, Uzbekistan, Vanuatu, Vatican City, Venezuela, Vietnam, Wallis and Futuna, Western Sahara, Yemen, Zambia, Zimbabwe Show more Show less

- Available

Mini-Project for control solutions

Thank you for reaching out to ZP regarding control solutions where you intend to control solutions to calibrate a multi-monitoring meter, which is based on a silicon-printed electrode.

The solutions you require are:

> Glucose

> Hemoglobin

> Creatinine

> Uric Acid

> Cholesterol

As discussed through several emails ZP does not necessarily have an off the shelf solution for you, and so ZP would produce the first batch of solutions as a mini-project. A mini project is designed to gather the client's requirements and design the solutions according to those needs.

ZP is an international company and we are capable of shipping globally using FCA intercom terms.

Please note that the programme can be purchased below by credit card, by clicking the ADD TO CART.

Mini Projects

A mini-project from ZP is an effort of 32 hours, all efforts are capped at 32 hours and therefore it is imperative that the client team is also efficient to allow ZP to be able to deliver value.

Any 3rd party costs will be charged at cost plus 15 %.

Mini Projects from ZP

32 hours of effort. All 3rd party costs will be charged in addition at cost plus 15 %

11.499,00 €

Final price

Free shipping to the following countries: Afghanistan, Albania, Andorra, Angola, Anguilla, Antarctica, Antigua and Barbuda, Armenia, Netherlands Antilles, United Arab Emirates , Algeria, American Samoa, Argentina, Aruba, Australia, Austria, Azerbaijan, Bahamas, Bahrain, Bangladesh, Barbados, Belarus, Belgium, Belize, Benin, Bermuda, Bhutan, Bolivia, Bosnia and Herzegovina, Botswana, Bouvet Island, Brazil, British Indian Ocean Territory, British Virgin Islands, Brunei, Bulgaria, Burkina Faso, Burundi, Cambodia, Cameroon, Canada, Cape Verde, Cayman Islands, Central African Republic, Chad, Chile, China, Christmas Island, Cocos [Keeling] Islands, Colombia, Comoros, Congo - Brazzaville, Congo - Kinshasa, Cook Islands, Costa Rica, Côte d’Ivoire, Croatia, Cuba, Cyprus, Czech Republic, Denmark, Djibouti, Dominica, Dominican Republic, Ecuador, Egypt, El Salvador, Equatorial Guinea, Eritrea, Estonia, Ethiopia, Falkland Islands, Faroe Islands, Fiji, Finland, France, French Guiana, French Polynesia, French Southern Territories, Gabon, Gambia, Georgia, Germany, Ghana, Gibraltar, Greece, Greenland, Grenada, Guadeloupe, Guam, Guatemala, Guinea, Guinea-Bissau, Guyana, Haiti, Heard Island and McDonald Islands, Honduras, Hong Kong SAR China, Hungary, Iceland, India, Indonesia, Iran, Iraq, Ireland, Israel, Italy, Jamaica, Japan, Jordan, Kazakhstan, Kenya, Kiribati, Kuwait, Kyrgyzstan, Laos, Latvia, Lebanon, Lesotho, Liberia, Libya, Liechtenstein, Lithuania, Luxembourg, Macau SAR China, Macedonia, Madagascar, Malawi, Malaysia, Maldives, Mali, Malta, Marshall Islands, Martinique, Mauritania, Mauritius, Mayotte, Mexico, Micronesia, Moldova, Monaco, Mongolia, Montenegro, Montserrat, Morocco, Mozambique, Myanmar [Burma], Namibia, Nauru, Nepal, Netherlands, New Caledonia, New Zealand, Nicaragua, Niger, Nigeria, Niue, Norfolk Island, Northern Mariana Islands, North Korea, Norway, Oman, Pakistan, Palau, Palestinian Territories, Panama, Papua New Guinea, Paraguay, Peru, Philippines, Pitcairn Islands, Poland, Portugal, Puerto Rico, Qatar, Réunion, Romania, Russia, Rwanda, Saint Barthélemy, Saint Helena, Saint Kitts and Nevis, Saint Lucia, Saint Martin, Saint Pierre and Miquelon, Saint Vincent and the Grenadines, Samoa, San Marino, São Tomé and Príncipe, Saudi Arabia, Senegal, Serbia and Montenegro, Seychelles, Sierra Leone, Singapore, Slovakia, Slovenia, Solomon Islands, Somalia, South Africa, South Georgia and the South Sandwich Islands, South Korea, Spain, Sri Lanka, Sudan, Suriname, Svalbard and Jan Mayen, Swaziland, Sweden, Switzerland, Syria, Taiwan, Tajikistan, Tanzania, Thailand, Timor-Leste, Togo, Tokelau, Tonga, Trinidad and Tobago, Tunisia, Turkey, Turkmenistan, Turks and Caicos Islands, Tuvalu, Uganda, Ukraine, United Kingdom, United States, Uruguay, U.S. Minor Outlying Islands, U.S. Virgin Islands, Uzbekistan, Vanuatu, Vatican City, Venezuela, Vietnam, Wallis and Futuna, Western Sahara, Yemen, Zambia, Zimbabwe Show more Show less

- Available

Python code for Randles-Sevcik Equation

# -*- coding: utf-8 -*-

"""

Created on Sun Jan 5 10:50:40 2025

@author: martp

"""

import numpy as np

import matplotlib.pyplot as plt

# Constants

n = 1 # Number of electrons transferred

A = 0.0416 # Electrode area in cm²

D = 6.0e-6 # Diffusion coefficient in cm²/s

C_mol_L = 5e-3 # Concentration in mol/L

blocking = 0.0 # Fraction of the electrode area blocked (0.5 means 50% blocked)

F = 96485 # Faraday constant in C/mol

R = 8.314 # Gas constant in J/(mol*K)

T = 298 # Temperature in K

# Convert concentration from mol/L to mol/cm³

C = C_mol_L / 1000 # 1 L = 1000 cm³

# Adjust the effective electrode area due to blocking

effective_area = A * (1 - blocking) # Effective area after blocking

# Randles-Sevcik constant at 298 K

k = 2.69e5

# Scan rates in V/s (logarithmic range for better visualization)

v = np.logspace(-3, 1, 500) # From 0.001 to 10 V/s

# Calculate peak current using Randles-Sevcik equation and convert to microamps

Ip_microA = k * n**1.5 * effective_area * D**0.5 * C * v**0.5 * 1e6 # Convert A to µA

# Plot

plt.figure(figsize=(8, 6))

plt.plot(v, Ip_microA, label=f'n={n}, Effective A={effective_area:.2f} cm², D={D} cm²/s, C={C_mol_L} mol/L, Blocking={blocking*100:.0f}%')

plt.xscale('log') # Logarithmic scale for scan rate

plt.yscale('log') # Logarithmic scale for peak current

plt.xlabel('Scan Rate (V/s)', fontsize=12)

plt.ylabel('Peak Current (µA)', fontsize=12)

plt.title('Randles-Sevcik Equation: Peak Current vs Scan Rate (With Blocking)', fontsize=14)

plt.grid(which='both', linestyle='--', linewidth=0.5)

plt.legend(fontsize=10)

plt.tight_layout()

plt.show()

Shipping charges and terms at ZP

Zimmer and Peacock at the time of writing this note has been in business for over 10 years and so it is with this experience we write this note on shipping procedures and costs from ZP to clients.

ZP's shipping terms are often FCA, we appreciate that potential clients sometimes would like to organise shipping themselves, and have products picked up from our site. We have found from long experience that this results in putting extra costs onto ZP as we still have to package and label the good, we have to meet and greet the courier, we have to provide contact details for the courier, and we have found that client couriers are not always correctly booked, or do not arrive for several weeks.

Therefore to streamline our operations ZP will provide the shipping inline with the details we have provided through the webstore, quote etc.

Continuous lactate monitoring (CLM) in athletes - trials

Continuous lactate monitoring in athletes is challenging, to break down the barriers ZP is offering paid trials of ZP's CLM technology at our site in Norway, please contact ZP to find out more.

Developers Kit for Lead Detection

The Pb/lead detection and quantification kit from ZP allows researchers/developers/academics/businesses/entrepreneurs to explore lead detection in their applications: from soil, to water to blood.

ZP Lecture at DYPBBI

Here is a recording of the event.

Zimmer and Peacock's CSO Dr Martin Peacock will be giving an invited online lecture to colleagues at DYPPBI DATE - 11 October 2024

TIME: 11:30 AM to 12:30 PM on

TITLE: Enzyme based electrochemical biosensors.

Enquiry Form

The form on this page is intended only for those who have been sent a link to this page. The form is a series of questions for those who are looking to engage with ZP's Technologies and Services around biosensors.

SenseItAll (SIA) for glucose and uric acid measurement

SenseItAll is an OEM sensor platform that measures analytes in samples.

On this page we have the the SIA OEM kit for developers, start-ups and businesses who want to bring glucose sensing and uric into their solution offering.

SIA is part of ZP's sensor to API platform so every measurement ends up in the Cloud and can be pulled across to third party Clouds via an API call.

Glucose and Uric Acid SenseItAll Kit

ZP1001694

Glucose SenseItAll Kit includes:

- SenseItAll instrument (ZP1001451)

- SenseItAll mobile App

- Pack of 100 glucose sensors (ZP1001692)

- SenseItAll Glucose Solution Pack (ZP1001693)

- Pack of 100 uric acid sensors (ZPS URA-000-00070)

- A complimentary 12 month license to Djuli.

8.299,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Sold Out

SenseItAll (SIA) Specifications

Welcome to the SenseItAll potentiostat for educators, researchers, developers, entrepreneurs and businesses looking to educate, explore, publish and commercialise electrochemical assays.

Developers Kit for Multi-analyte reader for water quality

ZP is an ISO13485 contract developer and manufacturer of electrochemical biosensor technologies. Our business model is to work with entrepreneurs, businesses, academics and developers to enable their products, ideas and applications.

On this page we discuss our Cloud Enabled SIA solution with nitrate sensors.

Nitrate SenseItAll Developer Kit

Nitrate SenseItAll Kit includes:

- SenseItAll Instrument (ZP1001451)

- SenseItAll mobile App

- Pack of 50 nitrate sensors

- SenseItAll Solution Pack

- A complimentary 12 month license to Djuli.

5.899,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Sold Out

pack of 50 pH Gen2 sensors

2.500,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Sold Out

pack of 50 TAC sensors

2.500,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Sold Out

SenseItAll Library

Zimmer and Peacock's SenseItAll (SIA) platform is designed to help bring our business and academic clients to market with their ideas and technologies.

On this page we demonstrate the versatility of the platform, including: potassium, nitrate, pH, total antioxidant capacity, glucose, gingerol and capsaicin.

Download the Android App.

Download the iPhone App.

Developers Kit - SenseItAll (SIA) with 50 nitrate sensors

ZP is an ISO13485 contract developer and manufacturer of electrochemical biosensor technologies. Our business model is to work with entrepreneurs, businesses, academics and developers to enable their products, ideas and applications.

On this page we discuss our Cloud Enabled SIA solution with nitrate sensors.

Nitrate SenseItAll Developer Kit

Nitrate SenseItAll Kit includes:

- SenseItAll Instrument (ZP1001451)

- SenseItAll mobile App

- Pack of 50 nitrate sensors

- SenseItAll Solution Pack

- A complimentary 12 month license to Djuli.

5.899,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Sold Out

Developers Kit - SenseItAll (SIA) with 100 purine sensors

ZP is an ISO13485 contract developer and manufacturer of electrochemical biosensor technologies. Our business model is to work with entrepreneurs, businesses, academics and developers to enable their products, ideas and applications.

On this page we discuss our Cloud Enabled SIA solution with purine sensors.

Purine SenseItAll Developer Kit

Purine SenseItAll Kit includes:

- SenseItAll Instrument (ZP1001451)

- SenseItAll mobile App

- Pack of 100 purine

- SenseItAll Solution Pack

- A complimentary 12 month license to Djuli.

19.999,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Sold Out

Developers Kit - SenseItAll (SIA) with 100 nitrate sensors

ZP is an ISO13485 contract developer and manufacturer of electrochemical biosensor technologies. Our business model is to work with entrepreneurs, businesses, academics and developers to enable their products, ideas and applications.

On this page we discuss our Cloud Enabled SIA solution with nitrate sensors.

Nitrate SenseItAll Developer Kit

Nitrate SenseItAll Kit includes:

- SenseItAll Instrument (ZP1001451)

- SenseItAll mobile App

- Pack of 100 nitrate sensors

- SenseItAll Solution Pack

- A complimentary 12 month license to Djuli.

7.299,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Sold Out

Developers Kit - SenseItAll (SIA) with 100 ATP sensors

ZP is an ISO13485 contract developer and manufacturer of electrochemical biosensor technologies. Our business model is to work with entrepreneurs, businesses, academics and developers to enable their products, ideas and applications.

On this page we discuss our Cloud Enabled SIA solution with phosphate sensors.

ATP SenseItAll Developer Kit

ATP SenseItAll Kit includes:

- SenseItAll Instrument (ZP1001451)

- SenseItAll mobile App

- Pack of 100 ATP Sensors

- SenseItAll Solution Pack

- A complimentary 12 month license to Djuli.

7.299,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Available

- Generally ships within 3-4 weeks

FoodSense Chillie Testing Service

Samples can be sent to ZP Norway for testing on FoodSense prior to purchasing a FoodSense Generation 4 of your own.

Samples are sent at your expense and ZP requires 5 g or more of a sample. If it's a tasty sauce then please just send us the whole bottle and we'll finish it off.

Testing samples

125,00 €

Final price

Free shipping to the following countries: Afghanistan, Albania, Andorra, Angola, Anguilla, Antarctica, Antigua and Barbuda, Armenia, Netherlands Antilles, United Arab Emirates , Algeria, American Samoa, Argentina, Aruba, Australia, Austria, Azerbaijan, Bahamas, Bahrain, Bangladesh, Barbados, Belarus, Belgium, Belize, Benin, Bermuda, Bhutan, Bolivia, Bosnia and Herzegovina, Botswana, Bouvet Island, Brazil, British Indian Ocean Territory, British Virgin Islands, Brunei, Bulgaria, Burkina Faso, Burundi, Cambodia, Cameroon, Canada, Cape Verde, Cayman Islands, Central African Republic, Chad, Chile, China, Christmas Island, Cocos [Keeling] Islands, Colombia, Comoros, Congo - Brazzaville, Congo - Kinshasa, Cook Islands, Costa Rica, Côte d’Ivoire, Croatia, Cuba, Cyprus, Czech Republic, Denmark, Djibouti, Dominica, Dominican Republic, Ecuador, Egypt, El Salvador, Equatorial Guinea, Eritrea, Estonia, Ethiopia, Falkland Islands, Faroe Islands, Fiji, Finland, France, French Guiana, French Polynesia, French Southern Territories, Gabon, Gambia, Georgia, Germany, Ghana, Gibraltar, Greece, Greenland, Grenada, Guadeloupe, Guam, Guatemala, Guinea, Guinea-Bissau, Guyana, Haiti, Heard Island and McDonald Islands, Honduras, Hong Kong SAR China, Hungary, Iceland, India, Indonesia, Iran, Iraq, Ireland, Israel, Italy, Jamaica, Japan, Jordan, Kazakhstan, Kenya, Kiribati, Kuwait, Kyrgyzstan, Laos, Latvia, Lebanon, Lesotho, Liberia, Libya, Liechtenstein, Lithuania, Luxembourg, Macau SAR China, Macedonia, Madagascar, Malawi, Malaysia, Maldives, Mali, Malta, Marshall Islands, Martinique, Mauritania, Mauritius, Mayotte, Mexico, Micronesia, Moldova, Monaco, Mongolia, Montenegro, Montserrat, Morocco, Mozambique, Myanmar [Burma], Namibia, Nauru, Nepal, Netherlands, New Caledonia, New Zealand, Nicaragua, Niger, Nigeria, Niue, Norfolk Island, Northern Mariana Islands, North Korea, Norway, Oman, Pakistan, Palau, Palestinian Territories, Panama, Papua New Guinea, Paraguay, Peru, Philippines, Pitcairn Islands, Poland, Portugal, Puerto Rico, Qatar, Réunion, Romania, Russia, Rwanda, Saint Barthélemy, Saint Helena, Saint Kitts and Nevis, Saint Lucia, Saint Martin, Saint Pierre and Miquelon, Saint Vincent and the Grenadines, Samoa, San Marino, São Tomé and Príncipe, Saudi Arabia, Senegal, Serbia and Montenegro, Seychelles, Sierra Leone, Singapore, Slovakia, Slovenia, Solomon Islands, Somalia, South Africa, South Georgia and the South Sandwich Islands, South Korea, Spain, Sri Lanka, Sudan, Suriname, Svalbard and Jan Mayen, Swaziland, Sweden, Switzerland, Syria, Taiwan, Tajikistan, Tanzania, Thailand, Timor-Leste, Togo, Tokelau, Tonga, Trinidad and Tobago, Tunisia, Turkey, Turkmenistan, Turks and Caicos Islands, Tuvalu, Uganda, Ukraine, United Kingdom, United States, Uruguay, U.S. Minor Outlying Islands, U.S. Virgin Islands, Uzbekistan, Vanuatu, Vatican City, Venezuela, Vietnam, Wallis and Futuna, Western Sahara, Yemen, Zambia, Zimbabwe Show more Show less

- Sold Out

Developers Kit - SenseItAll (SIA) with 100 phosphate sensors

ZP is an ISO13485 contract developer and manufacturer of electrochemical biosensor technologies. Our business model is to work with entrepreneurs, businesses, academics and developers to enable their products, ideas and applications.

On this page we discuss our Cloud Enabled SIA solution with phosphate sensors.

Phosphate SenseItAll Developer Kit

Phosphate SenseItAll Kit includes:

- SenseItAll Instrument (ZP1001451)

- SenseItAll mobile App

- Pack of 100 spectrum sensors

- SenseItAll Solution Pack

- A complimentary 12 month license to Djuli.

7.299,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Sold Out

Developers Kit - SenseItAll (SIA) with 100 spectrum (Pb) sensors

ZP is an ISO13485 contract developer and manufacturer of electrochemical biosensor technologies. Our business model is to work with entrepreneurs, businesses, academics and developers to enable their products, ideas and applications.

On this page we discuss our Cloud Enabled SIA solution with spectrum (Pb) sensors

Pb SenseItAll Developer Kit

Pb SenseItAll Kit includes:

- SenseItAll Instrument (ZP1001451)

- SenseItAll mobile App

- Pack of 100 spectrum sensors

- SenseItAll Solution Pack

- A complimentary 12 month license to Djuli.

7.299,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Sold Out

Developers Kit - SenseItAll (SIA) with 100 ammonium sensors

ZP is an ISO13485 contract developer and manufacturer of electrochemical biosensor technologies. Our business model is to work with entrepreneurs, businesses, academics and developers to enable their products, ideas and applications.

On this page we discuss our Cloud Enabled SIA solution with ammonium sensors

Ammonium SenseItAll Developer Kit

Potassium SenseItAll Kit includes:

- SenseItAll Instrument (ZP1001451)

- SenseItAll mobile App

- Pack of 100 ammonium sensors (ZPS NH4-000-00076)

- SenseItAll Ammonium Solution Pack (ZP1001690)

- A complimentary 12 month license to Djuli.

7.299,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Sold Out

SenseItAll (SIA) for cortisol measurement

SenseItAll is an OEM sensor platform that measures analytes in samples.

On this page we have the the SIA OEM kit for developers, start-ups and businesses who want to bring cortisol sensing into their solution offering.

SIA is part of ZP's sensor to API platform so every measurement ends up in the Cloud and can be pulled across to third party Clouds via an API call.

Cortisol SenseItAll Kit

ZP1001694

Glucose SenseItAll Kit includes:

- SenseItAll Instrument (ZP1001451)

- SenseItAll mobile App

- Pack of 100 cortisol sensors

- SenseItAll Cortisol Solution Pack

- A complimentary 12 month license to Djuli.

7.299,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Sold Out

SenseItAll Instrument

ZP1001451

The SenseItAll (SIA) instrument performs

electrochemical measurements and features Bluetooth connectivity, enabling seamless data upload and analysis on the Djuli cloud-based data management platform via the SenseItAll mobile

application. Included is a complimentary 12 month license to Djuli.

1.749,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Sold Out

Cortisol SenseItAll Solution Pack

Cortisol test solutions for testing the cortisol sensors with the SenseItAll meter. The test solutions comes in volumes of 50 mL.

500,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Sold Out

Cortisol sensor cartridge pack

Pack of cortisol sensors with SIA cartridges

2.800,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Sold Out

12 month subscription to Djuli

A 12 month subscription to Djuli and a 100 free hypervalue screen printed electrodes

948,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Sold Out

Unboxing SIA

SenseItAll (SIA) is an OEM solution from ZP for all those looking to develop products utilizing electrochemical sensors and assays. On this page we show what's in the box.

SenseItAll (SIA) with 100 potassium sensors

ZP is an ISO13485 contract developer and manufacturer of electrochemical biosensor technologies. Our business model is to work with entrepreneurs, businesses, academics and developers to enable their products, ideas and applications.

On this page we discuss our Cloud Enabled SIA solution with potassium sensors

Potassium SenseItAll Kit

ZP1001689

Potassium SenseItAll Kit includes:

- SenseItAll Instrument (ZP1001451)

- SenseItAll mobile App

- Pack of 100 potassium sensors (ZP1001691)

- SenseItAll Potassium Solution Pack (ZP1001690)

- A complimentary 12 month license to Djuli.

7.299,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Sold Out

SenseItAll Instrument

ZP1001451

The SenseItAll (SIA) instrument performs electrochemical measurements

and features Bluetooth connectivity, enabling seamless data upload and analysis on the Djuli cloud-based data management platform via the SenseItAll mobile application. Included is a complimentary 12 month license to Djuli.

1.749,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Sold Out

Potassium SenseItAll Solution Pack

ZP1001690

Potassium test solutions; mM, for testing the potassium sensors with the SenseItAll meter. The test solutions comes in volumes of 50 mL.

500,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Sold Out

Potassium sensor cartridge pack

ZP1001691

Pack of potassium sensors with SIA cartridges

2.800,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Sold Out

12 month subscription to Djuli

A 12 month subscription to Djuli and a 100 free hypervalue screen printed electrodes

948,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Sold Out

Alternative Djuli URLS

On this pager we have three Djuli logos, each logo is linked to an alternative URL for our Djuli server, we appreciate that in different parts of the world, sometimes not all URLS work due to local conditions,

Please click these logos to see if one of them will work for you.

SenseItAll (SIA) with 100 sodium sensors

ZP is an ISO13485 contract developer and manufacturer of electrochemical biosensor technologies. Our business model is to work with entrepreneurs, businesses, academics and developers to enable their products, ideas and applications.

On this page we discuss our Cloud Enabled SIA solution with sodium sensors

Sodium SenseItAll Kit

ZP1001702

Sodium SenseItAll Kit includes:

- SenseItAll Instrument (ZP1001451)

- SenseItAll mobile App

- Pack of 100 sodium sensors (ZP1001703)

- SenseItAll Sodium Solution Pack (ZP1001704)

- A complimentary 12 month license to Djuli.

7.299,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Available

- Generally ships within 3-4 weeks

SenseItAll Instrument

ZP1001451

The SenseItAll (SIA) instrument performs electrochemical measurements

and features Bluetooth connectivity, enabling seamless data upload and analysis on the Djuli cloud-based data management platform via the SenseItAll mobile application. Included is a complimentary 12 month license to Djuli.

1.749,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Sold Out

Sodium SenseItAll Solution Pack

ZP1001704

Sodium test solutions; mM, for testing the sodium sensors with the SenseItAll meter. The test solutions comes in volumes of 50 mL.

500,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Available

- Generally ships within 3-4 weeks

Sodium sensor cartridge pack

ZP1001703

Pack of sodium sensors with SIA cartridges

2.800,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Available

- Generally ships within 3-4 weeks

12 month subscription to Djuli

A 12 month subscription to Djuli and a 100 free hypervalue screen printed electrodes

948,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Sold Out

SenseItAll (SIA) for glucose measurement

SenseItAll is an OEM sensor platform that measures analytes in samples.

On this page we have the the SIA OEM kit for developers, start-ups and businesses who want to bring glucose sensing into their solution offering.

SIA is part of ZP's sensor to API platform so every measurement ends up in the Cloud and can be pulled across to third party Clouds via an API call.

Detection of B9 and B12 status in patients

ZP, a contract developer and manufacturer of electrochemical biosensors for point-of-care diagnostics, offers the SIA platform to efficiently guide businesses and developers from concept to product realization. This page focuses on our role in measuring Vitamin B9 and B12 using our SenseItAll (SIA) platform. To find out how SIA can be used in your clinical offering please attend our next webinar.

Vitamin B9, also known as folate or folic acid, and vitamin B12 are important for various functions in the body:

Cell Division and DNA Synthesis:

Vitamin B9 (Folate): It is crucial for cell division and the synthesis of DNA. Adequate folate levels are particularly important during periods of rapid cell division, such as during pregnancy and infancy.

Vitamin B12: Along with folate, vitamin B12 is essential for the synthesis of DNA and the normal functioning of cells, including the production of red blood cells in bone marrow.

Red Blood Cell Formation:

Vitamin B9 (Folate): Folate plays a key role in the production of red blood cells. A deficiency in folate can lead to megaloblastic anemia, where red blood cells are larger than normal.

Vitamin B12: Essential for the formation of red blood cells, a deficiency in vitamin B12 can also result in megaloblastic anemia.

Neurological Function:

Vitamin B9 (Folate): Folate is important for normal neurological function. Deficiencies in folate have been linked to neurological disorders and cognitive decline.

Vitamin B12: It is crucial for the maintenance of the nervous system. Deficiencies in vitamin B12 can lead to neurological problems, including tingling in the hands and feet and problems with memory and concentration.

Methylation Processes:

Vitamin B9 (Folate) and B12: Both vitamins are involved in methylation processes, which are essential for a variety of bodily functions, including the regulation of gene expression and the breakdown of homocysteine, an amino acid linked to cardiovascular disease.

During Pregnancy:

Vitamin B9 (Folate): Adequate folate is critical during pregnancy to prevent neural tube defects in the developing fetus.

Vitamin B12: Important for the development of the nervous system in the fetus.

Detection of Glucose-6-phosphate dehydrogenase (G6PD) deficiency in patients

ZP, a contract developer and manufacturer of electrochemical biosensors for point-of-care diagnostics, offers the SIA platform to efficiently guide businesses and developers from concept to product realization. This page focuses on our role in identifying Glucose-6-phosphate dehydrogenase (G6PD) deficiency.

Malaria, caused by Plasmodium species, affects millions annually. A cure requires 8-aminoquinoline therapy, targeting acute blood and dormant liver stages. Primaquine and tafenoquine, the only available hypnozoitocidal therapies, can cause acute hemolytic anemia in G6PD-deficient individuals. Clinicians are hesitant to prescribe them due to the high population prevalence of individuals with G6PD deficiency.

The World Health Organization (WHO) recommends higher doses of transmission-blocking primaquine and tafenoquine for patients with known G6PD status, therefore highlighting the need for a G6PD point-of-care diagnostic.

SenseItAll (SIA) for alcohol/ethanol measurement

SenseItAll is an OEM sensor platform that measures analytes in samples.

On this page we have the the SIA OEM kit for developers, start-ups and businesses who want to bring alcohol sensing into their solution offering.

SIA is part of ZP's sensor to API platform so every measurement ends up in the Cloud and can be pulled across to third party Clouds via an API call.

Alcohol SenseItAll Kit

ZP1001705

Alcohol SenseItAll Kit includes:

- SenseItAll instrument (ZP1001451)

- SenseItAll mobile App

- Pack of 100 alcohol sensors (ZP1001706)

- SenseItAll Alcohol Solution Pack (ZP1001707)

- A complimentary 12 month license to Djuli.

7.299,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Sold Out

SenseItAll Instrument

ZP1001451

The SenseItAll (SIA) instrument performs electrochemical measurements

and features Bluetooth connectivity, enabling seamless data upload and analysis on the Djuli cloud-based data management platform via the SenseItAll mobile application. Included is a complimentary 12 month license to Djuli.

1.749,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Sold Out

Alcohol SenseItAll Solution Pack

ZP1001707

Ethanol test solutions; %, for testing the alcohol sensors with the SenseItAll meter. The test solutions comes in volumes of 50 mL.

500,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Sold Out

Alcohol sensor cartridge pack

ZP1001706

Pack of alcohol sensors with SIA cartridges

2.800,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Sold Out

12 month subscription to Djuli

A 12 month subscription to Djuli and a 100 free hypervalue screen printed electrodes

948,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Sold Out

Calibration Free pH SenseItAll (SIA) Developers Kit

ZP is an ISO13485 contract developer and manufacturer of electrochemical biosensor technologies. Our business model is to work with entrepreneurs, businesses, academics and developers to enable their products, ideas and applications.

On this page we discuss our Cloud Enabled SIA solution for making calibration free pH measurements.

pH SenseItAll Kit

ZP1001699

pH SenseItAll Kit includes:

- SenseItAll Instrument (ZP1001451)

- SenseItAll mobile App

- Pack of 100 pH sensors (ZP1001700)

- SenseItAll pH Solution Pack (ZP1001701)

- A complimentary 12 month license to Djuli.

7.299,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Sold Out

SenseItAll Instrument

ZP1001451

The SenseItAll (SIA) instrument performs electrochemical measurements

and features Bluetooth connectivity, enabling seamless data upload and analysis on the Djuli cloud-based data management platform via the SenseItAll mobile application. Included is a complimentary 12 month license to Djuli.

1.749,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Sold Out

pH SenseItAll Solution Pack

ZP1001701

pH test solutions; pH 4, 7 and 10, for testing the pH sensors with the SenseItAll meter. The test solutions comes in volumes of 50 mL.

500,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Available

- Generally ships within 3-4 weeks

pH sensor cartridge pack

ZP1001700

Pack of pH generation 2 sensors with SIA cartridges

2.800,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Sold Out

12 month subscription to Djuli

A 12 month subscription to Djuli and a 100 free hypervalue screen printed electrodes

948,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Sold Out

SenseItAll (SIA) Potentiostat

A unique potentiostat from ZP, designed to close the gap between academic lab experiments and products that can impact society.

ZP is closing the translation gap between academia and business and crossing the chasm.

FoodSense for alcohol/ethanol measurement

FoodSense is a food and beverage quality platform that measures analytes and properties in food as part of food quality assurance during food and beverage production.

At the time of writing FoodSense is able to do capsaicin in chilli, gingerol in ginger and total anti-oxidative status (TAS). On this page ZP is reaching out to people seeking to measure alcohol/ethanol in a fast, low cost and convenient manner on a Cloud enabled device which backups and saves all their test results to the Cloud.

Alcohol SenseItAll Kit

ZP1001705

Alcohol SenseItAll Kit includes:

- SenseItAll Instrument (ZP1001451)

- SenseItAll mobile App

- Pack of 100 alcohol sensors (ZP1001706)

- SenseItAll Alcohol Solution Pack (ZP1001707)

- A complimentary 12 month license to Djuli.

7.299,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Sold Out

SenseItAll Instrument

ZP1001451

The SenseItAll (SIA) instrument performs electrochemical measurements

and features Bluetooth connectivity, enabling seamless data upload and analysis on the Djuli cloud-based data management platform via the SenseItAll mobile application. Included is a complimentary 12 month license to Djuli.

1.749,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Sold Out

Alcohol SenseItAll Solution Pack

ZP1001707

Ethanol test solutions; %, for testing the alcohol sensors with the SenseItAll meter. The test solutions comes in volumes of 50 mL.

500,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Sold Out

Alcohol sensor cartridge pack

ZP1001706

Pack of alcohol sensors with SIA cartridges

2.800,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Sold Out

12 month subscription to Djuli

A 12 month subscription to Djuli and a 100 free hypervalue screen printed electrodes

948,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Sold Out

SenseItAll Wearable/Watch

Welcome to the SenseItAll platform, as part of SenseItAll ZP has a wearable watch format that can be used to drive the majority of our ZP sensors.

ZP SenseItAll (SIA) Watch

2.499,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Sold Out

Wearable Biosensors

ZP is an ISO13485 innovative contract developer and manufacturer of electrochemical sensors, biosensors and assays, including wearable systems.

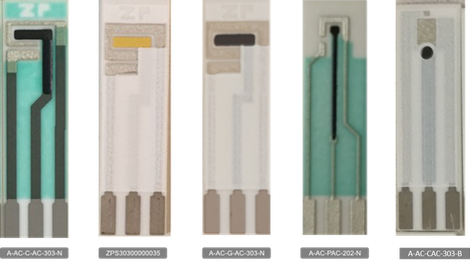

ZP launches 501 Screen Printed Platinum Electrodes

ZP manufactures the world's most reproducible screen printed electrodes that therefore leads to the most repeatable performance when incorporated into academic experiments or commercial development programmes.

ZP sells these electrodes in perforated sheets of 100 electrodes, so they are super easy to store and super easy to cingulate from the sheet.

The working electrode is platinum, the counter electrode is silver/silver chloride and the reference electrode is silver/silver chloride. The working electrode and counter electrode are sized so as not to limit performance on the working electrode.

To order, please go to our new Webstore here

Click the adjacent button to find out what makes the ZP electrodes so good.

ZP launches 501 Screen Printed Carbon Electrodes

ZP manufactures the world's most reproducible screen printed electrodes that therefore leads to the most repeatable performance when incorporated into academic experiments or commercial development programmes.

ZP sells these electrodes in perforated sheets of 300 electrodes, so they are super easy to store and super easy to cingulate from the sheet.

The working electrode is carbon, the counter electrode is carbon and the reference electrode is silver/silver chloride. The working electrode and counter electrode are sized so as not to limit performance on the working electrode.

To order 501 carbon SPE, please go to our new Webstore here.

SenseItAll (SIA) -OEM Image Gallery

Welcome to our photo gallery of the SenseItAll (SIA) platform.

SIA is an OEM solution that our collaborators can use in their products.

Early Bird Registration and Receive Early Bird Discount - S3 UK

Early Bird 2 Day pass to Expo and Conference

Secure an early bird 2 Day pass to Conference and Expo

450,00 €

Final price

Free shipping to the following countries: Afghanistan, Albania, Andorra, Angola, Anguilla, Antarctica, Antigua and Barbuda, Armenia, Netherlands Antilles, United Arab Emirates , Algeria, American Samoa, Argentina, Aruba, Australia, Austria, Azerbaijan, Bahamas, Bahrain, Bangladesh, Barbados, Belarus, Belgium, Belize, Benin, Bermuda, Bhutan, Bolivia, Bosnia and Herzegovina, Botswana, Bouvet Island, Brazil, British Indian Ocean Territory, British Virgin Islands, Brunei, Bulgaria, Burkina Faso, Burundi, Cambodia, Cameroon, Canada, Cape Verde, Cayman Islands, Central African Republic, Chad, Chile, China, Christmas Island, Cocos [Keeling] Islands, Colombia, Comoros, Congo - Brazzaville, Congo - Kinshasa, Cook Islands, Costa Rica, Côte d’Ivoire, Croatia, Cuba, Cyprus, Czech Republic, Denmark, Djibouti, Dominica, Dominican Republic, Ecuador, Egypt, El Salvador, Equatorial Guinea, Eritrea, Estonia, Ethiopia, Falkland Islands, Faroe Islands, Fiji, Finland, France, French Guiana, French Polynesia, French Southern Territories, Gabon, Gambia, Georgia, Germany, Ghana, Gibraltar, Greece, Greenland, Grenada, Guadeloupe, Guam, Guatemala, Guinea, Guinea-Bissau, Guyana, Haiti, Heard Island and McDonald Islands, Honduras, Hong Kong SAR China, Hungary, Iceland, India, Indonesia, Iran, Iraq, Ireland, Israel, Italy, Jamaica, Japan, Jordan, Kazakhstan, Kenya, Kiribati, Kuwait, Kyrgyzstan, Laos, Latvia, Lebanon, Lesotho, Liberia, Libya, Liechtenstein, Lithuania, Luxembourg, Macau SAR China, Macedonia, Madagascar, Malawi, Malaysia, Maldives, Mali, Malta, Marshall Islands, Martinique, Mauritania, Mauritius, Mayotte, Mexico, Micronesia, Moldova, Monaco, Mongolia, Montenegro, Montserrat, Morocco, Mozambique, Myanmar [Burma], Namibia, Nauru, Nepal, Netherlands, New Caledonia, New Zealand, Nicaragua, Niger, Nigeria, Niue, Norfolk Island, Northern Mariana Islands, North Korea, Norway, Oman, Pakistan, Palau, Palestinian Territories, Panama, Papua New Guinea, Paraguay, Peru, Philippines, Pitcairn Islands, Poland, Portugal, Puerto Rico, Qatar, Réunion, Romania, Russia, Rwanda, Saint Barthélemy, Saint Helena, Saint Kitts and Nevis, Saint Lucia, Saint Martin, Saint Pierre and Miquelon, Saint Vincent and the Grenadines, Samoa, San Marino, São Tomé and Príncipe, Saudi Arabia, Senegal, Serbia and Montenegro, Seychelles, Sierra Leone, Singapore, Slovakia, Slovenia, Solomon Islands, Somalia, South Africa, South Georgia and the South Sandwich Islands, South Korea, Spain, Sri Lanka, Sudan, Suriname, Svalbard and Jan Mayen, Swaziland, Sweden, Switzerland, Syria, Taiwan, Tajikistan, Tanzania, Thailand, Timor-Leste, Togo, Tokelau, Tonga, Trinidad and Tobago, Tunisia, Turkey, Turkmenistan, Turks and Caicos Islands, Tuvalu, Uganda, Ukraine, United Kingdom, United States, Uruguay, U.S. Minor Outlying Islands, U.S. Virgin Islands, Uzbekistan, Vanuatu, Vatican City, Venezuela, Vietnam, Wallis and Futuna, Western Sahara, Yemen, Zambia, Zimbabwe Show more Show less

- Sold Out

Exhibitor pass (table plus delegate)

Exhibit at the event

1.300,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Sold Out

Flow adaptor for screen printed electrodes

Ana Flow Adapter

This adapter is perfectly made for our 7mm ceramic sensors. This gives you the opportunity to create a controlled and continuous flow over the sensing area.

It comes with a LM4 connector that is suitable with ZP Anapot, before you order contact us to let us know about the connectors to your potentiostat.

950,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Sold Out

Multianalyte testing

ZP is integrating our range of sensors into a multi-analyte platform for new markets including Food and Beverage.

ZP Developers Zone 8 AM London 11 May 2023

A weekly webinar from ZP, please note the webinar is recorded so no need to watch live.

ZP Developers Zone 8 AM London 4 May 2023

A weekly webinar from ZP, please note the webinar is recorded so no need to watch live.

ZP Developers Zone 8 AM London 27 April 2023

A weekly webinar from ZP, please note the webinar is recorded so no need to watch live.

ZP Developers Zone 8 AM London 20 April 2023

A weekly webinar from ZP, please note the webinar is recorded so no need to watch live.

Proof of principle (POP) studies at ZP with MVP and Planning for Next Phase

A proof of principle (POP) study at ZP, leading to an prototype/MVP is a short three to six month programme, typically about 1500 hours of effort,, where ZP takes the work and understanding already with our collaborators and translates it onto our ZP platforms.

The purpose of the work is to bring the work from its current status and move it onto a platform that ZP sees can be manufactured within our ISO13485 facility. We would look to deliver a minimally viable product, suitable for for showing tangible hardware to stakeholders, such as investors. The MVP may not be ready for roll out into unsupervised clinical settings

The understanding that the client has regarding their electrochemical assay or biosensor, this can include:

1) Practical work already undertaken.

2) Academic papers from the literature.

3) Patents licensed/owned by the collaborator.

The stages in a proof of principle programme

The effort in a ZP proof of principle programme (PoP) is a time and materials effort and ZP will work within the constraints of the budget of approximately 1500 hours.

In a POP programme ZP will:

1) STEP ONE - Perform a tech transfer or discussion with the client to understand the status of the technology and learn all the tips, tricks and anecdotes that the client can give to make ZP's efforts as efficient as possible.

2) STEP TWO - ZP will suggest one or more first small pieces of work within the POP, which we will discuss with the client before proceeding. These suggestions are based on where the technology is today and where does the technology need to be in terms of the market/clinical requirements. ZP will work through the work to see which of the ideas both works and is commercially viable. The number of ideas worked upon is constrained by the budget.

3) STEP THREE - ZP will give online update meetings where we will give a presentation on the work done and the results so far. ZP is happy to receive comments and feedback from the clients.

4) STEP FOUR - As we progress through the study we will start to plan the next phase of work.

Please note that ZP will build a presentation for the client as we work, in addition ZP can produce reports, procedures etc. All work can be done within the constraints of the budget.

Proof of principle study - ZP

Please note that all consumables, chemicals, 3rd party cost services and materials etc required to deliver on the programme are charged at cost plus 15 %

360.000,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Available

- Generally ships within 3-4 weeks

For those developing an IVD click the adjacent button to read a discussion getting to market.

ZP Developers Zone 8 AM London 13 April 2023

A weekly webinar from ZP, please note the webinar is recorded so no need to watch live.

ZP Developers Zone 8 AM London 6 April 2023

A weekly webinar from ZP, please note the webinar is recorded so no need to watch live.

ZP Developers Zone 8 AM London 30 March 2023

A weekly webinar from ZP, please note the webinar is recorded so no need to watch live.

ZP Developers Zone 8 AM London 23 March 2023

A weekly webinar from ZP, please note the webinar is recorded so no need to watch live.

ZP Developers Zone 8 AM London 16 March 2023

A weekly webinar from ZP, please note the webinar is recorded so no need to watch live.

ZP Developers Zone 8 AM London 9 March 2023

A weekly webinar from ZP, please note the webinar is recorded so no need to watch live.

Single purpose biosensor circuit

This kit is a starter pack that includes a ZP's single-purpose biosensor board, an adapter. and an FTDI-USB cable for communicating with the biosensor board. It's a great way to set up your system quickly. Additionally, the biosensor board can be easily removed from the adapter, allowing you to use another sensor-specific biosensor board if needed on the same adapter.

To order, please go to our new Webstore.

ZP Developers Zone 8 AM London 2 March 2023

A weekly webinar from ZP, please note the webinar is recorded so no need to watch live.

ZP Developers Zone 8 AM London 23 February 2023

A weekly webinar from ZP, please note the webinar is recorded so no need to watch live.

ZP Developers Zone 8 AM London 16 February 2023

A weekly webinar from ZP, please note the webinar is recorded so no need to watch live.

Emma - six channel potentiostat

A true six channel potentiostat able to measure the six channels at the same time. The potentiostat is WIFI enabled and is ideal for developers and manufacturers of electrochemical biosensors, electrochemical sensors and assays: electrochemical impedance, amperometry, open circuit potential, voltammetry etc.

Please contact ZP before purchase to discuss your application.

Each unit comes with a Djuli license.

ZP Developers Zone 8 AM London 9 February 2023

A weekly webinar from ZP, please note the webinar is recorded so no need to watch live.

ZP Developers Zone 8 AM London 2 February 2023

A weekly webinar from ZP, please note the webinar is recorded so no need to watch live.

ZP Chloridization Process

ZP is happy to license our chloritization process for 1 M Euros per annum.

License to ZP Chloridization Process

A 1 year license to ZP's chloridization process can be licensed at 1 M Euros per annum.

1.000.000,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Sold Out

ZP Subscriptions

ZP Subscriptions are for those who want a lighter effort, but extended interaction with ZP. These subscriptions are 12 month commitments from ZP and the client. The ZP subscription takes advantage of ZP's Matrix Organization Structure.

ZP has three levels of subscription per month, and are intended for those who want a lighter effort with ZP:

1) Nano subscription - 2 hours per month 796 Euros per month for 12 months.

2) Micro subscription - 15 hours per month, 4,999 Euros per month for 12 months.

3) Mini subscription - 32 hours per month, 9,999 Euros per month for 12 months.

4) Standard subscription - 90 hours per month, 19,999 Euros per month for 12 months.

ZP Subscription

The ZP Subscription is for those who are looking for lighter interaction with ZP..

796,00 €

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- Available

- Generally ships within 3-4 weeks

ZP Developers Zone 8 AM London 26 January 2023

A weekly webinar from ZP, please note the webinar is recorded so no need to watch live.

ZP Developers Zone 8 AM London 19 January 2023

A weekly webinar from ZP, please note the webinar is recorded so no need to watch live.

ZP Developers Zone 8 AM London 12 January 2023

A weekly webinar from ZP, please note the webinar is recorded so no need to watch live.

ZP Developers Zone 8 AM London 5 January 2023

A weekly webinar from ZP, please note the webinar is recorded so no need to watch live.

CGM Capabilities at ZP

As part of our frequent ZP Developer Zone Webinars we discussed our CGM capabilities at ZP.

ZP Developers Zone 8 AM London 29 December 2022

A weekly webinar from ZP, please note the webinar is recorded so no need to watch live.

Eight Working Electrode Array

The adjacent item is our 8 working electrode array based on our carbon hyper value electrode.

Eight working electrode array