At ZP we manufacture our pH solid state pH within our ISO13485 quality management system, applying our standard operating procedures/work instructions and our acceptance criteria. To characterize our solid state pH sensors manufacturing ZP has carried out a multi-step investigation.

STEP ONE - Manufacturing phase

ZP performed a manufacturing step where we manufactured three batches of 108 pH sensors on three different days.

STEP TWO - Testing phase

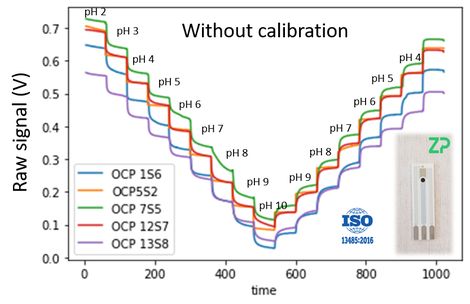

Next ZP functionally tested five random sensors from each batch. The solid state pH sensors were tested with pH solutions between pH 2 to pH 10, please see adjacent raw data. As a side note ZP is unusual in that we have both high-throughput manufacturing capability and high-throughput testing capability, click here. This functional test capability was used in this study.

STEP THREE - Data processing phase

Having gathered the data ZP then used our data processing group to apply a mathematical baseline correction to the data, where we mathematically moved all of the data to a baseline of 0 V at the initial pH 2, please see the adjacent data.

This baseline correction is equivalent to a one point calibration. It should be noted that an even more accurate way of calibrating pH sensors is of course to perform a two point calibration, but it was unnecessary for this study. Click here to see our data group.

STEP FOUR - Data analysis phase

Having processed the data ZP next analysed the data.

ZP has a very sophisticated set of technologies and workflows in-house for the conversion of data into actionable information, click here to find out more.

STEP FIVE - Reporting results phase

The result of our testing was that across all three batches and having performed a single baseline correction 75 % of all the sensors within the population of 324 pH sensors gave a measured result that was within 85 % of the actual result, i.e. for a pH of 7, the overwhelming majority of the pH sensors from the three batches would read a value in the range 5.95 to 8.05.

STEP TWO

STEP THREE

STEP FOUR