There are several ways of working with ZP and one of those is a collaboration where we fabricate sensors/electrodes and you (our collaborator) functional test the sensors/wafers.

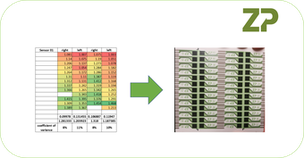

The reason collaborations work with Zimmer and Peacock is because we have a seamless way of you linking the test data you gather with our manufacturing data, what this means is that we are able to link sensor function with sensor manufacturing this allows us to understand how manufacturing is affecting performance and allows us to improve issues like sensor variation and sensor sensitivity.

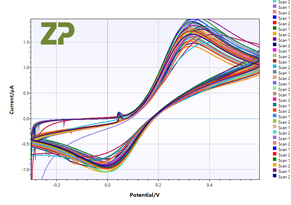

Zimmer and Peacock is the only company that electrochemically characterizes our off-the-shelf screen printed electrodes, in a process we call wafer mapping.

ZP stores the data in a proprietary Cloud electrochemical data storage system called Djuli - click the adjacent image to discover djuli.

Zimmer and Peacock cam use a number of techniques in our wafer mapping process including cyclic voltammetry, as part of our wafer mapping strategy.

Note this wafer mapping data was gathered at 50 mV/s, in 1 mM ferrocyanide.

As discussed when ZP is manufacturing sensors for a customer, client or collaborator one of the investigations we to perform is wafer mapping. Essentially wafer mapping means tracking a sensor from manufacturing all the way through to functional testing, so we can spot whether there is a link between how a sensor finally performs and it's position within the manufacturing run.

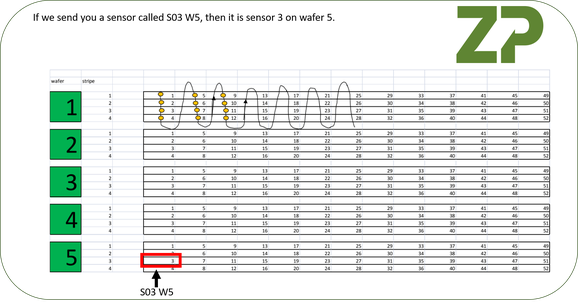

When we are working with a client we perform wafer mapping as part of product performance, the practicality is that we will be sending you hundreds if not thousands of sensors/electrodes to you for testing, each sensor comes with a unique identifier number (UIN).

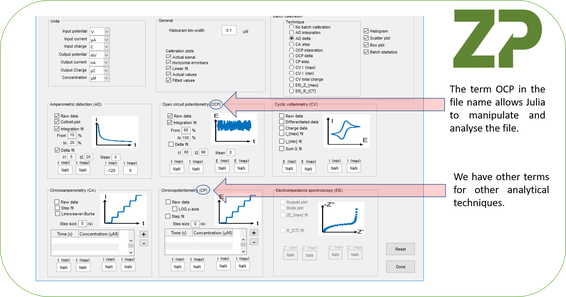

In the images below we explain the source of the UIN, and how if you include the UIN in the file name then Julia (our Cloud database) will automatically analyse the data and create wafer maps, calibration curves, figures of merit etc.

The source of the UIN is that we make sensors/electrodes in wafers, and within a wafer are a number of sensors. In the adjacent image we show an electrode batch is made of five wafers and that there are 52 sensors/electrodes within the wafer.

If we send you a sensor/electrode with the UIN S03 W5 then it is sensor/electrode 3 on wafer 5.

You will receive sensors/electrodes from us, for example S03 W5 and you will test it. For example you might test it with 2 microM of analyte and analyse it by open circuit potential. We are assuming that you are using one of the AnaPot instruments.

Next we need you to save the data into the Julia database. For this example the filename would be, 2 uM S03 W5 OCP.pst

The logic for the file name is that it tells us that it was 2 microM of analyte tested on sensor/electrode S03 W5 and the method of analysis was open circuit potential.

The OCP is important as Julia can do the mass manipulation of data and extract information from the the raw signals gathered in the lab.

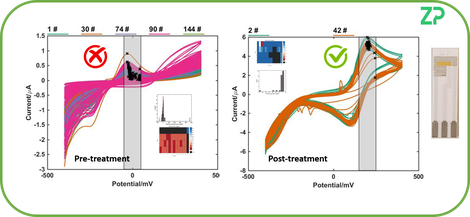

ZP is very different from all other manufactures of electrodes and biosensors, including those where a gold electrode is at the heart of the technology. In the adjacent image we show how we surface treat our gold screen printed electrodes to ensure that the surface is pristine for their subsequent use in electrochemical investigations.