Welcome to this week's newsletter from Zimmer and Peacock. This newsletter is a mixture of news, stories and tech notes from Zimmer and Peacock. If you want to subscribe to our newsletter or have any questions regarding Zimmer and Peacock and our passion for biosensor technologies please don't hesitate to contact us.

ZP - Validating a clinical analyser in a new application

At ZP we are developers and manufacturers of biosensors and medical diagnostics, but we are always focused on the objectives of our clients, and so if we think an instrument already exists that will move our client forward rapidly we will purchase it, validate it and put it to work in that programme. In this video we are doing just that with the PetScan 2 from Abaxis.

Smiles all round after a successful demonstration

Two happy ZP team members after a successful ChilliPot - Scoville Meter demonstration!

Zimmer and Peacock are passionate about technology that improves lives and business. The ChilliPot - Scoville Meter is just one of those products, as it makes decision making in the Food Industry fact based, as the ChilliPot - Scoville Meter is an objective measurement on the hotness of Chilli products.

Validation of the Chilli Sensor Technology

In this video we discuss the amount of development that has taken place in our labs to ensure the chilli hotness technology is robust for the real world.

ZP - Contract CGM Development and Manufacturing

Zimmer and Peacock has one of the most experienced independent CGM development and manufacturing teams in the world. Our industrial experience in CGM development comes from several years of developing and troubleshooting CGM sensors in Europe and North America.

Working with Zimmer and Peacock on your development is straightforward as we meet, discuss and advise you on the unique features you want to bring to your CGM, and then we will produce a technical proposal to work against.

Questions and discussion points include:

Linearity – What linearity is required?

Resolution – What glucose resolution do you require, e.g. 0.1 mM/2 mg/dL?

Stability of signal – When in 5 mM/90 mg/dL concentration of glucose for how long is the signal stable before showing ± 10 % deviation.

Interferences – How sensitive is the sensor to interferences, such as acetaminophen and ascorbic acid.

Which sterilization technique will we apply?

Biocompatibility, a discussion on the wetted materials and the medical grade materials we will use.

Test jigs for the parallel testing of biosensors

The parallel testing of biosensors and medical diagnostics is important when developing and manufacturing.

Zimmer and Peacock produce tests rigs for the high throughout testing of biosensors as part of our clients' development and manufacturing programmes.

If you have a question regarding biosensor development and manufacturing please feel free to contact us.

An interview with a ZP founder

ZP is successful at making our customers and collaborators successful and getting their biosensors and medical diagnostics into the clinic.

In this interview our director discusses what motivates us and how we develop and manufacture biosensors for others others.

Zahner and ZP live webinar - recording

Zahner and Zimmer and Peacock held a live webinar where Zahner demonstrated their latest software. If you have any questions for Zahner and ZP please don't hesitate to contact us.

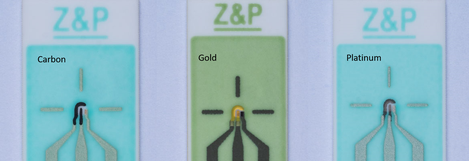

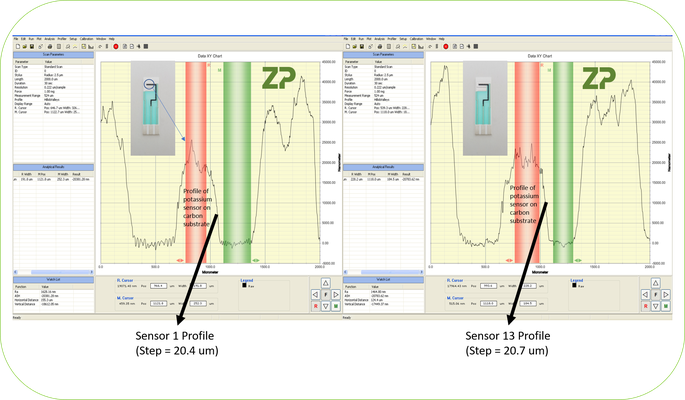

Profilometry analysis of ZP Sensors

At Zimmer and Peacock we are happy to be helpful. In this image our collaborator asked us to get profilometry data on our sensor and being the company that we are, we were happy to do that.

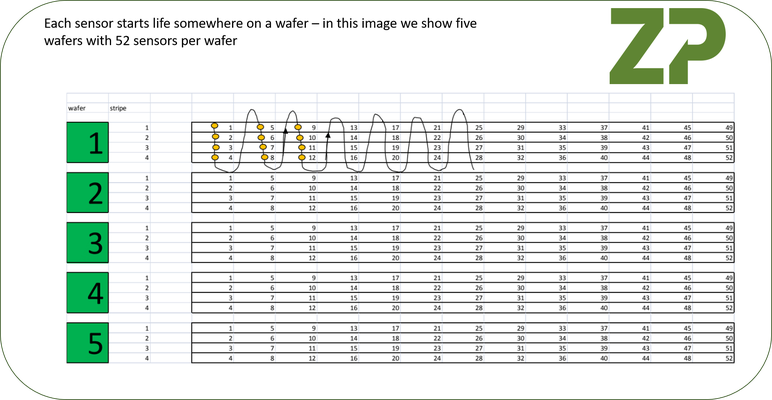

Biosensor Wafer Mapping and Functional Testing

There are several ways of working with ZP and one of those is a collaboration where we fabricate sensors/electrodes and you (our collaborator) functional test the sensors/wafers.

The reason collaborations work with Zimmer and Peacock is because we have a seamless way of you linking the test data you gather with our manufacturing data. This means that we are able to link sensor function with sensor manufacturing this allows us to understand how manufacturing is affecting performance and allows us to improve issues like sensor variation and sensor sensitivity.

When we are manufacturing the sensors for a customer, client or collaborator one of the investigations we to perform is wafer mapping. Essentially wafer mapping means tracking a sensor from manufacturing all the way through to functional testing, so we can spot whether there is a link between how a sensor finally performs and it's position within the manufacturing run.

When we are working with a client we perform wafer mapping as part of product performance, the practicality is that we will be sending you hundreds if not thousands of sensors/electrodes to you for testing, each sensor comes with a unique identifier number (UIN). Find out more on our website here.