Zimmer and Peacock is an ISO13485 contract developer and manufacturer of electrochemical biosensors. One of the workflows within ZP is the thick film printing of electrodes and then their subsequent functionalization with materials to give them specificity to the analyte of interest. On this page we discuss some non-destructive analysis at ZP to determine coating quality.

Functionalization

Zimmer and Peacock has several techniques for functionalizing an electrode, including: self-assembled monolayer (SAM), electro-deposition, drop-coating, dip-coating etc.

ZP is unusual in that we are able to perform functional testing of the sensors using the analytes of interest but we are of course also able to perform passive/non-destructive testing.

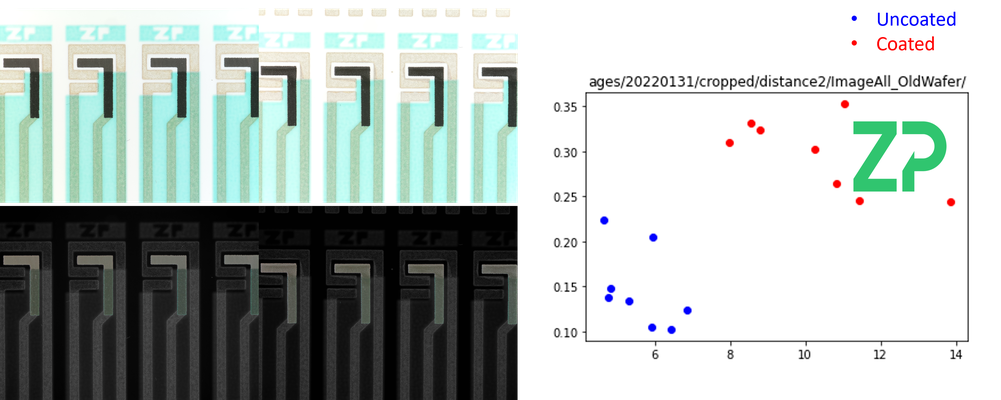

On this page we discuss ZP vision technology for imaging the working electrode and quantifying the coverage of the working electrode.

Non-destructive testing

In the adjacent image we compare four electrodes with: zero coatings, single coatings, two coatings, three coatings. The ZP technology can colour code the working electrodes to determine the coverage of the electrodes, see Figure 1.0.0.

The ZP non-destructive analysis similarly allows us to automatically detect features on the electrodes, see Figure 1.0.1.