Welcome to this week's newsletter from Zimmer and Peacock. This newsletter is a mixture of news, stories and tech notes from Zimmer and Peacock. If you want to subscribe to our newsletter or have any questions regarding Zimmer and Peacock and our passion for biosensor technologies please don't hesitate to contact us.

Variation in screen-printed electrodes

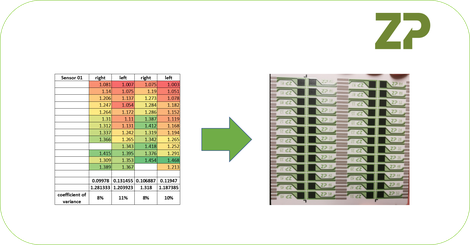

At Zimmer and Peacock we are the only manufacturer of screen printed electrodes, biosensor, sensors and medical diagnostics who wafer-map our electrodes.

For certain types of electrochemical sensors the signal is proportional to the working electrode area and so ZP is unique in that we functionally test the working electrode as part of our manufacturing process.

In the adjacent image we have tested 52 electrodes with a standard solution using cyclic voltammetry. We have measured the peak height and have collected all the data we can see how the signal/peak height changes across the wafer. We can see that for this wafer our coefficient of variation is approximately 10%.

If someone was using this wafer to make sensors where the method of analysis was EIS (electrochemical impedance spectroscopy) or an amperometric technique we would report advise that the best variation they could expect is 10%, if they wanted better precision we would select electrodes from the wafer which we would take forward to convert into sensors.

Pt electrodes as biosensors

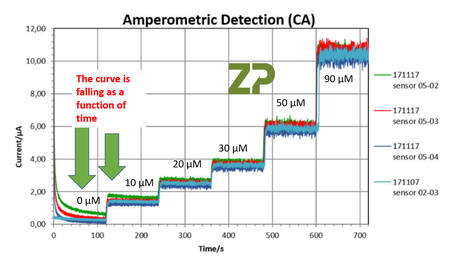

Zimmer and Peacock had a collaborator who was using a ZP platinum sensors in a flow cell. The user was wondering why the signal looked like it was changing at the beginning of the assay.

In the adjacent image you can see how the signal was changing when tested with 0 micromolar hydrogen peroxide.

The answer to this question can have a number of sources but an obvious answer is that the Pt is undergoing conversion from Pt to PtO2. The observation in the lab is often that someone will use at Pt electrode and the signal may take some time to settle, but then on further use of the electrode the electrode is stable. What we suspect at ZP is that the first time you use a sensor it is Pt but as soon a you apply a voltage, maybe 650 mV vs reference electrode then you will convert the top layer of Pt to PtO2. As the platinum is consumed the current due to this process diminishes until the signal becomes stable.